Whitepaper

Reducing the Cost of Biologics with Enzene’s Flagship End-to-End Fully-Connected Continuous Manufacturing™ Technology

Reducing the Cost of Biologics with Enzene’s Flagship Endto-End Fully-Connected Continuous Manufacturing™ Technology

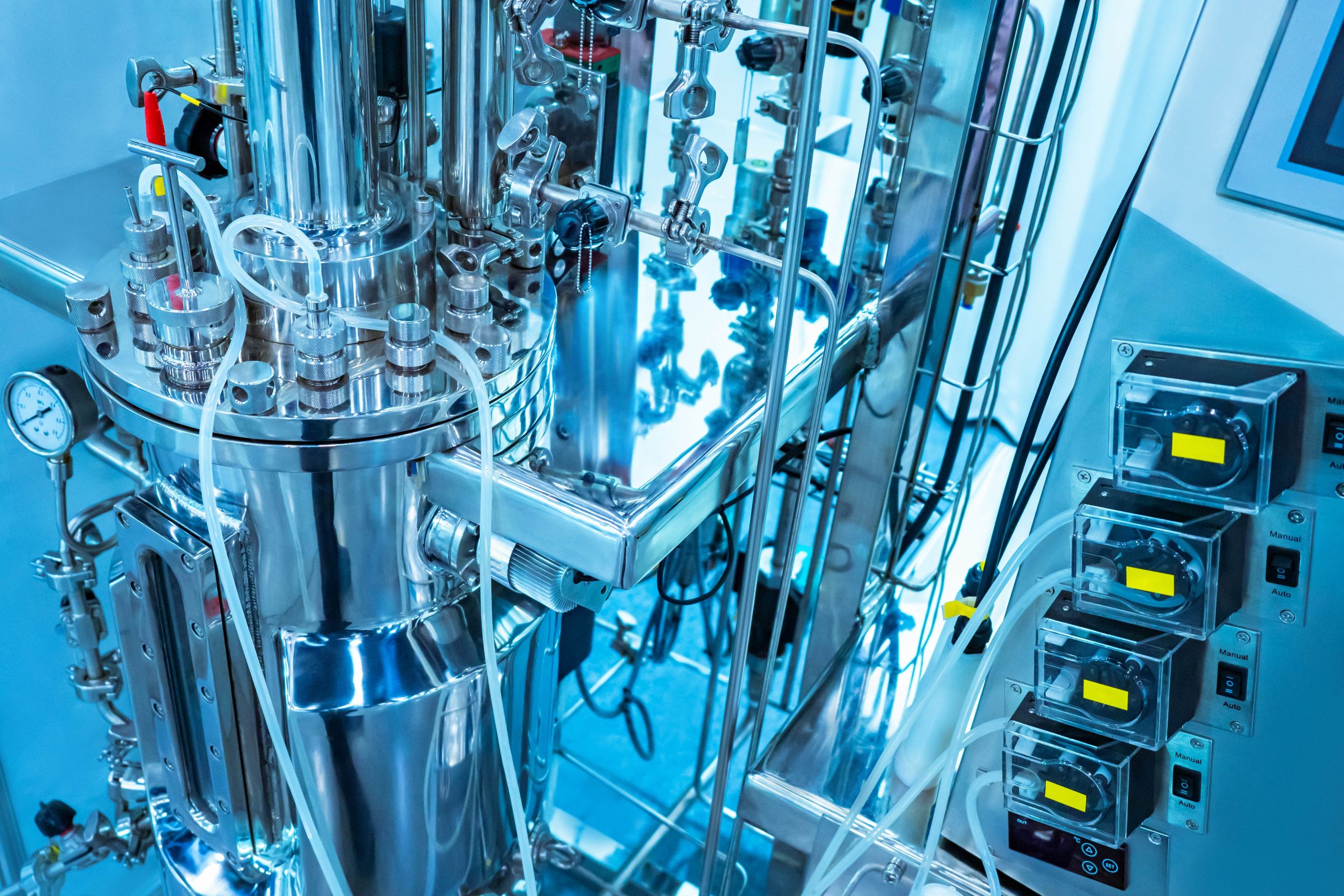

Despite growing global demand for biologics, high production costs remain one of the biggest barriers to widespread patient access.

Biologics are inherently more complex and costly to manufacture than small-molecule drugs, and require more time, specialized infrastructure, and highly-skilled labor to produce. High costs are attributed to specialized raw materials, advanced equipment, and labor-intensive processes, which are rooted in the industry’s long-standing reliance on batch manufacturing.

Traditional fed-batch manufacturing, the current standard, is constrained by its stepwise nature and characterized by multiple discrete stages, extended production times, large footprint, and inherent inefficiencies. These factors significantly hinder scalability and cost control. Semi-continuous manufacturing, while offering moderate improvements in yield and efficiency, still retains many of the limitations associated with batch-based systems.

Fully-Connected Continuous Manufacturing™ (FCCM™), by contrast, marks a fundamental shift in biomanufacturing. By integrating upstream and downstream operations into a connected, real-time process, higher productivity, reduced cost of goods, smaller facility footprints, and improved product consistency can all be achieved.

Fields marked with a * are required